Introduction

The advancement of technology continues to push boundaries in various industries, and the field of quality control within manufacturing is no exception. Blaze Technology, LLC, a trailblazing innovator in automation solutions, has taken a remarkable step forward by developing a fully automated underwater meter test system. This groundbreaking achievement was made possible through their strategic partnership with Schneider Electric, National Instruments, Wildcat Electric, and the implementation of the M241 Programmable Logic Controller (PLC).

The Need for Automation in Underwater Meter Testing

Accurate metering is crucial for the natural gas industry. Natural gas is used for homes, restaurants, and various commercial and industrial needs. To ensure precise measurements, regular testing and calibration of meters are essential. However, meter testing poses unique challenges due to the complexity of the multitude of environments and the potential risks involved for human operators.

Traditionally, meter testing to meet certain IP ratings required manual intervention, often involving several technicians to work simultaneously using complicated setups. This approach not only posed safety risks but also lacked efficiency and consistency. Blaze Technology recognized these limitations and set out to develop an innovative solution that would address these challenges head-on.

Blaze Technology's Vision: A Fully Automated Solution

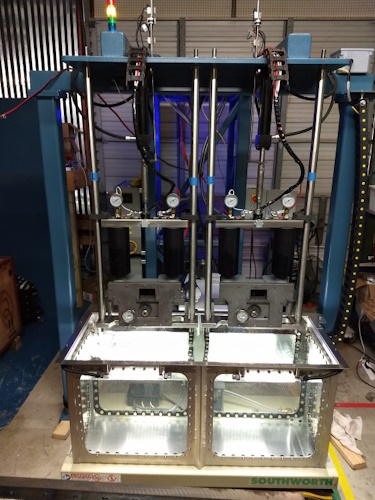

Blaze Technology's vision was to create a fully automated gas meter test system that would eliminate the need for human intervention, enhance accuracy, improve consistency, and improve overall testing efficiency. By achieving this, they aimed to revolutionize the way meter testing is conducted, making it safer, faster, and more reliable. Up to four meters could be tested simultaneously underwater and pressured internally with air to determine if any leaks were discovered. The leaks would show integrity issues with the meter housing.

The Role of Schneider Electric's M241 PLC

To bring their vision to life, Blaze Technology partnered with Schneider Electric, a global leader in industrial automation and energy management solutions. The heart of their fully automated system became the Schneider Electric M241 PLC. The M241 PLC, known for its high performance and versatility, was an ideal choice due to its robustness, scalability, and advanced programming capabilities. The use of Schneider Electric M241 PLC enabled Blaze Technology to develop a "set it and forget it" operation.

The Role of National Instrument's LabVIEW

In the realm of technological innovation, Blaze Technology, LLC, stands as a beacon of excellence, harnessing the synergy between LabVIEW and Microsoft SQL Server to pioneer advanced data storage solutions while upholding the highest standards of data integrity.

At the core of Blaze Technology's success lies their adept utilization of LabVIEW, a powerful graphical programming language widely employed in measurement and automation applications. Combining LabVIEW's versatile capabilities with the robustness of Microsoft SQL Server, they have established a seamless data storage ecosystem that guarantees not only efficient storage but also the steadfast integrity of crucial information. Through LabVIEW's intuitive interface, Blaze Technology engineers can effortlessly capture, process, and channel data from various sources, ensuring accurate and consistent data streams. This dynamic data is then seamlessly funneled into MS SQL Server's relational database structure, creating a cohesive repository that mirrors real-world relationships and enhances data organization.

Furthermore, Blaze Technology employs LabVIEW to implement data transformation and pre-processing workflows, ensuring that data entering MS SQL Server is appropriately formatted and ready for storage. This process minimizes the potential for data corruption, discrepancies, or duplication, reinforcing the reliability of the stored information.

Key Features and Benefits

Blaze Technology's fully automated meter test system offers several key features and benefits:

Fully Automated Operation: The M241 PLC allows for real time monitoring during the entire testing process. This feature is particularly valuable for testing meters in an underwater environment, as it eliminates the need for operators to be present during the tests, reducing risks and costs.

Precision and Accuracy:The automated system ensures consistent and precise testing, minimizing the potential for human errors and variations in results. This is crucial for maintaining the accuracy of meter measurements.

Efficiency and Speed: With automation, testing procedures can be executed with higher efficiency and speed compared to manual methods. This is especially advantageous for industries where time-sensitive readings are essential.

Data Logging and AnalysisThe M241 PLC teaming up with LabVIEW facilitates real-time data logging, enabling continuous monitoring and analysis of testing results. This data-driven approach enhances decision-making and helps identify any anomalies promptly.

Safety:By eliminating the need for human operators in the testing process, the system significantly improves safety for operators. This is particularly important in hazardous or challenging pressure and underwater environments.

Scalability:The modular design of the M241 PLC allows and the power of LabVIEW allows for incredible scalability, enabling Blaze Technology to customize the system to accommodate diverse types of meter testing requirements.

Conclusion

Blaze Technology, LLC's successful collaboration with Schneider Electric and National Instruments in developing a fully automated gas meter test system marks a significant milestone in of automation and industrial testing. This achievement showcases how innovative partnerships and cutting-edge technology can address complex challenges, streamline operations, and improve safety across industries.

The marriage of Blaze Technology's vision and Schneider Electric's M241 PLC and National Instruments LabVIEW highlights the potential for automation to reshape traditional practices. As technology continues to evolve, we can anticipate further advancements that will enhance efficiency, accuracy, and safety in a wide range of applications, ultimately driving progress and innovation forward.